WEBER extrusion

PEX lines

Up to 400

kg/h output capacity

NEXXT365

for the optimum cross linkage

PEXa Pipe extrusion

Your requirement: Pipes for extremely high thermal requirements. Our answer: Extruders and pipe heads for the extrusion of high-quality PEXa pipes. Due to the peroxidic cross linkage of HDPE, the PEXa-pipe ranks among the best of its type. PEXa-pipes are used specifically to meet extremely high requirements, e.g. in the heating and sanitary area, in geothermic systems, in the area of district heating or in the industry. For these powerful pipes, WEBER also offers powerful extruders and, in cooperation with the company IBA and I-Extrusion, especially customised complete production lines for pipes.

PEX lines

for extrusion with high thermal requirements

Output

| CE7 PEX | 35-100 kg/h |

|---|---|

| DS7 PEX | 60-120 kg/h |

| DS9 PEX | 80-400 kg/h |

Table with diameter range

| PKX1 | 8-32 mm |

| PKX2 | 16-63 mm |

| PKX3 | 63-160 mm |

Your benefits

at a glance

- IF-Screw® technology

- PEX-specific special solutions

- Many years of process engineering experience

- OS5 control system with open interfaces, e.g. OPC-UA, Euromap 27

- Cooperation partner with IBA and I-Extrusion

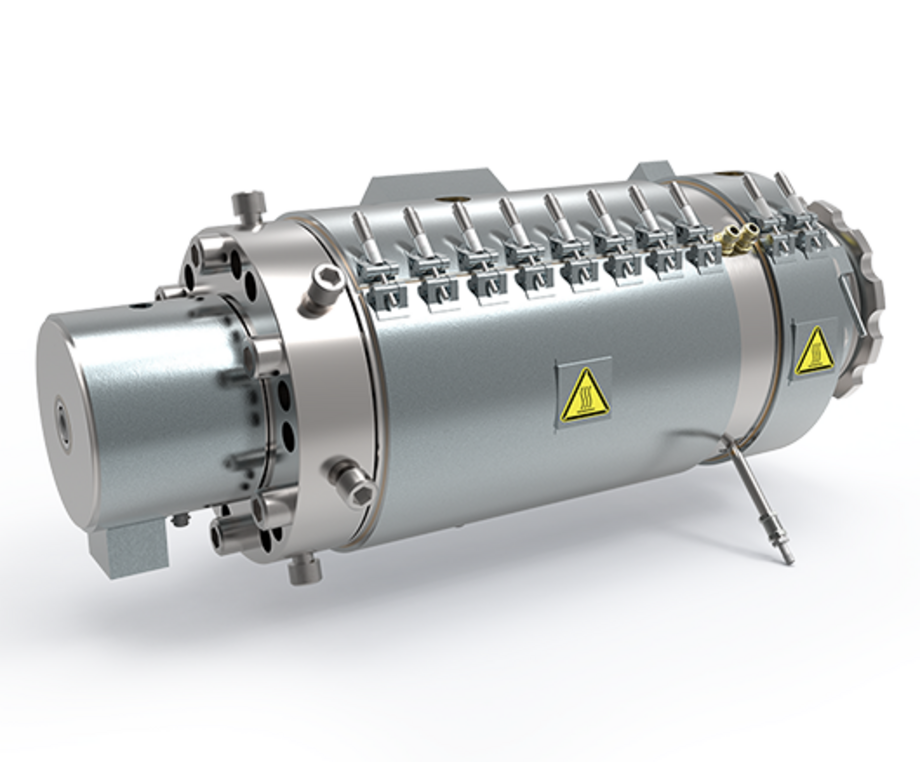

PEX pipe head for extrusion with high thermal requirements

WEBER service

Your extruder needs maintenance or wear parts need to be replaced? Contact our service team now. Our contacts and representatives are available worldwide to provide you with advice and assistance.

WEBER contact

Contact us now. We will be happy to advise you on the subject of extruder technology. Our contacts and representatives are available worldwide to provide you with advice and assistance.

Solutions for the future

Please contact us

Benefit from our expert knowledge: We will be pleased to advise you and together we will find a solution that will perfectly meet your requirements. Do not hesitate to contact us. We also develop your solution for the future together with you.