WEBER extrusion

PVC granulation lines

Up to 2500

kg/h output capacity

NEXXT365

for the optimum cross linkage

Resource-saving granulation of PVC

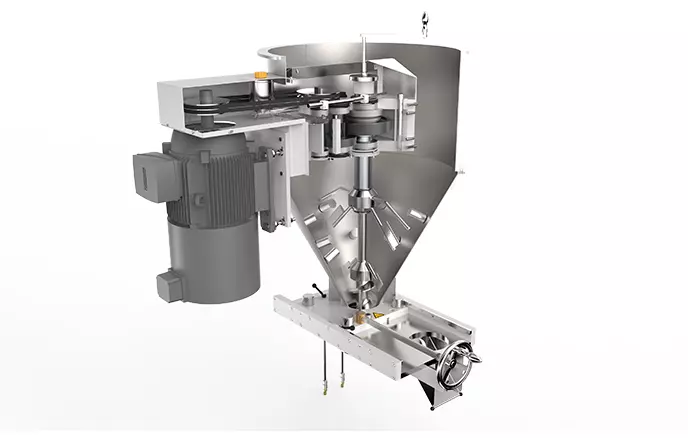

Less waste, more reuse. PVC granulation addresses the challenges of the circular economy and helps to reuse products as long as possible. There are various tasks to be addressed in the manufacturing of PVC granules. Granulation, recycling, upcycling of PVC dry-blend or milled material, new material or post-consumer material. With the optimally matched line components, WEBER offers complete lines for any demand. The new head granulator allows output capacities of up to 2500kg/h using the hot-cut method. With this, the emphasis is mainly on process safety, easy handling and consistently high quality of granules.

WEBER PVC granulation lines

Best product qualities with the IF-Screw® technology

| Model range | max. output PVC-P | max. output PVC-U pipe | max. output PVC-U profile |

|---|---|---|---|

| DS7.32G | 700 kg/h | 550 kg/h | 350 kg/h |

| DS9.32G | 1250 kg/h | 950 kg/h | 640 kg/h |

| DS12.32G | 1750 kg/h | 1400 kg/h | 950 kg/h |

| DS14.32G | 2500 kg/h | 2000 kg/h | 1240 kg/h |

WEBER service

Your extruder needs maintenance or wear parts need to be replaced? Contact our service team now. Our contacts and representatives are available worldwide to provide you with advice and assistance.

WEBER contact

Contact us now. We will be happy to advise you on the subject of extruder technology. Our contacts and representatives are available worldwide to provide you with advice and assistance.

Solutions for the future

Please contact us

Benefit from our expert knowledge: We will be pleased to advise you and together we will find a solution that will perfectly meet your requirements. Do not hesitate to contact us. We also develop your solution for the future together with you.